Paving the way to a more sustainable Europe

HYScale is at the forefront of a technological leap in hydrogen production. This initiative is reshaping the landscape with its advanced alkaline membrane water electrolysis (AMWE) technology, which stands out for its efficiency and sustainability. The HYScale method produces hydrogen at current densities far exceeding the industry standard, all without relying on critical raw materials or fluorinated components.

Marking a significant stride toward a greener future, HYScale’s technology is already meeting key performance indicators set for 2024, showcasing impressive advancements from the lab bench. This technology, developed from a series of EU-funded projects, is tailored for rapid and cost-effective upscaling.

Stack durability and stability

With a focus on environmental responsibility, HYScale is crafting a large-area stack, designed to have a 400 cm² active surface area and a powerful 100 kW nominal power. This stack is engineered to perform efficiently across a wide operational range, maintaining high durability and stability even at the ambitious current density of 2 A cm⁻² and at the modest operational temperature of 60 °C.

The project’s ambition crystalises with a targeted capital expenditure of only 400 € per kW, setting a new benchmark for affordability in the hydrogen industry. The integration of this stack into a functional electrolyser system, poised for validation in an industrially relevant setting at TRL5, represents a pivotal milestone. This achievement is expected to fast-track the transition from research to commercial viability, drastically reducing the time to market.

The HYScale endeavour is more than an industrial project; it’s a testament to how innovation can steer Europe towards a more sustainable and economically sound energy future. With its groundbreaking approach to hydrogen production, HYScale isn’t just making an impact; it’s setting the stage for a revolution in clean energy.

Our objectives

Improving Material Efficiency

Making the components of the HYScale electrolyser more efficient, durable, economical and environmentally sustainable for greener hydrogen production.

Large AEMWE Prototype

Creating a large electrolyser AEMWE stack (100 kW) integrated into a smart designed balance of plant (BoP) working under a wide range of conditions.

Ensuring Stability in Varied Conditions

Incorporating innovations into the HYScale electrolyser, robust management of energy supply fluctuations can be ensured when operated with or integrated into renewable sources.

Testing in Real-World Scenarios

Integrating a 100 kW system into a real-world setting to test its practicality and move it closer to being market-ready.

Demonstrating High Efficiency and Durability

Showing that HYScale system can work efficiently, using less electricity and maintaining its performance over time during real-world testing.

Reducing Operating Costs

Enhancing operational efficiency, minimising energy wastage, and reducing the system’s water quality requirements thanks a smart design.

Creating a Collaborative Ecosystem

Bringing together experts from different industries to create an innovative environment that supports the widespread use of the HYScale AEMWE technology.

Covering the entire production chain

HYScale team is setting up a model that includes every step of the production process, from the initial materials to the final HYScale system, to demonstrate a complete solution.

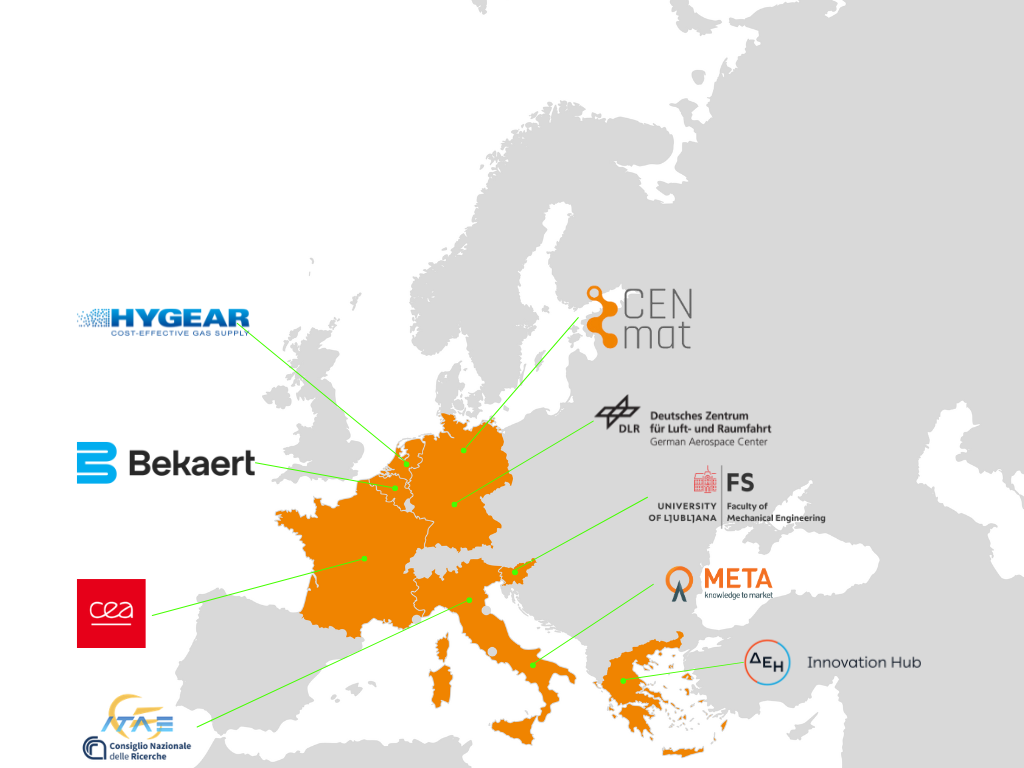

Partners

The HYScale project engages research institutes to support the industry with knowledge, highly sophisticated scientific methods for materials, components, and system analysis, as well as an additional channel for disseminating and exploiting the project results.

Cutting-Edge Nanomaterials UG (CENmat) is a company based in Pforzheim, Germany, founded in 2019 as a Spin-Off of the German Aerospace Center, with a focus on the development and manufacturing of electrolysers.

CENmat is a vertically integrated water electrolyser company built for the climate era. Their technologies allow the production of economical and truly green hydrogen with electrolyser technologies that are sustainable, scalable, highly efficient and low-cost for a green and fossil-free future.

Website: https://cen-mat.com/

Contribution: project coordination and management, membrane and electrode optimisation and upscale, production of membranes and electrodes for the stack.

As hydrogen technology provider, HyGear takes the lead in both hydrogen generation with a low or carbon-negative footprint and in the production and supply of sustainable gas.

Website: https://hygear.com/

Contribution: design of the demonstrator system.

Innovation Hub is the leading electricity generation and supply company in Greece with activities in the generation, distribution and sale of electricity to consumers. The PPC Group maintains a total installed generation capacity of 10.4 GW in Greece, with thermal and hydroelectric power plants as well as Renewable Energy Sources (RES) installations both on the mainland and on the islands.

Website: https://innovationhub.dei.gr/en/

Contribution: end-user testing the performance HYScale technology during demonstrations. The integrated fuel cell system will be transferred to the premises of PPC’s Innovation Hub, there to be connected to an electrical grid fed by RES (PVs, batteries) and subsequently to be tested for its performance.

Global market and technology leader in material science of steel wire transformation and coating technologies, Bekaert also applies its expertise beyond steel to create new solutions with innovative materials and services for markets including new mobility, low-carbon construction, and green energy.

Website: https://www.bekaert.com/

Contribution: act as a Porous Transport Layer (PTL) supplier for the anode side of the proposed AEM electrolyser.

Company addressing the entrepreneurial needs of those who are at the forefront of knowledge-intensive regions’ development: European Commission, regional governments & development agencies, public & private investors, research organisations, start-up companies & entrepreneurs.

Website: https://www.meta-group.com/

Contribution: exploitation partner involved also in the dissemination and communication activities.

National research institution of the Federal Republic of Germany focusing on aeronautics, space, transport and energy. The Electrochemical Energy Technology department of the Institute of Engineering Thermodynamics has many years of experience in the fields of fuel cells and water electrolysis (AEM, alkaline, PEM, SOEC). Using laboratory experiments and computer simulation, almost 200 employees research the scientific principles of electrochemical and thermochemical energy storage and evaluate the efficiency, costs and sustainability of future energy systems. and sustainability of future energy systems.

Website: https://www.dlr.de/TT

Contribution: design of the HYScale full stack with advanced components and reduced costs (100 kW) with an high active area for each cell (400 cm²), modelling and simulation of the stack based on single cell and short stack tests, pristine and post mortem component analysis including AFM, FIB-SEM, XPS, FTIR, etc. and cell testing and analysis.

The Institute of Advanced Technologies for Energy "N. Giordano" (ITAE) is one Institutes of the Engineering, ICT and Technologies for Energy and Transport Department (DIITET) of the Italian National Research Council (CNR). Within the Department, ITAE's strategic mission is mainly aimed at promoting and developing innovative energy processes and technologies with a higher efficiency and a lower environmental impact based on the use of fossil fuels (still available today) and/or renewable energy sources.

Website: https://www.cnr.it/

Contribution: design of large active area cell and short stack prototype, analysis, down-selection and optimisation of materials and components, manufacturing and testing of the short stack.

Major research organisation working in fundamental research, it is able to provide tangible solutions to meet their needs in four key fields: low-carbon energy (nuclear and renewable), digital technology, technology for medicine of the future, and defence and national security.

Website: https://www.cea.fr/

Contribution: electrode engineering and post mortem analyses.

The University of Ljubljana, Slovenia's oldest and largest higher education and research institution, is known for its outstanding achievements in the social, natural and technical sciences. The team at the Faculty of Mechanical Engineering (UL) brings the expertise in life cycle assessment, life cycle costing and social LCA, which is the result of many successful EU-funded Clean Hydrogen Partnership projects over the last five years, in which UL has been involved as a leader in the field of sustainability assessment.

Website: https://www.fs.uni-lj.si/

Contribution: environmental and techno-economic analysis.